The CEMIT AI

Data Platform

We make it as simple as collect, visualize, predict and act.

Able to integrate with any of your measurement tools, the Platform is a versatile data-driven AI solution that provides a comprehensive report on the state of your infrastructure. With its easy installation, immediate ROI, and continuous live-data feed, get ready to enjoy the advantages of a predict-and-prevent maintenance solution.

Our products & services

CEMIT AI Data Platform

The Platform represents the foundation of our data analysis software. With the convergence and processing of multiple sensor sources, you get results with meaningful insights, enabling the move towards data-driven decisions and predictive maintenance.

CEMIT AI Data Platform›The Platform represents the foundation of our data analysis software. With the convergence and processing of multiple sensor sources, you get results with meaningful insights, enabling the move towards data-driven decisions and predictive maintenance.

The Platform represents the foundation of our data analysis software. With the convergence and processing of multiple sensor sources, you get results with meaningful insights, enabling the move towards data-driven decisions and predictive maintenance.

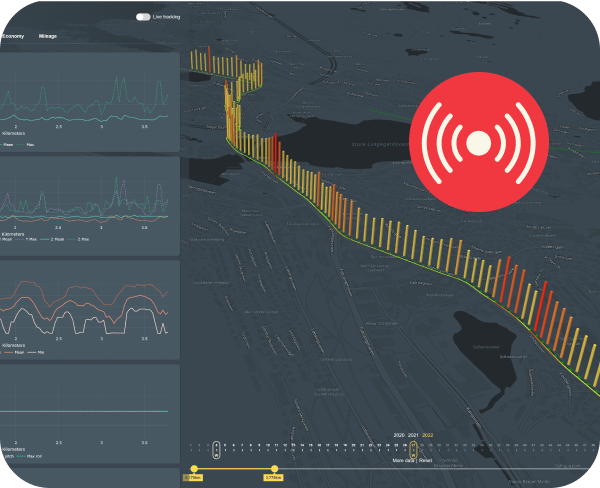

CEMIT Visualizer™›The Visualizer is an intuitive data dashboard that gives real time insight displayed in a user friendly and interactive way. It includes:

- Rail Prediction

- Catenary Prediction

- Switch prediction

- Train Prediction

- Depot Management

- Route Planner

The Visualizer is an intuitive data dashboard that gives real time insight displayed in a user friendly and interactive way. It includes:

- Rail Prediction

- Catenary Prediction

- Switch prediction

- Train Prediction

- Depot Management

- Route Planner

Custom Applications›The CEMIT AI Data Platform is designed to combine various data sources and different data analysis techniques. Such versatility can be extended to develop custom applications to fit your specific rail needs.

The CEMIT AI Data Platform is designed to combine various data sources and different data analysis techniques. Such versatility can be extended to develop custom applications to fit your specific rail needs.

Railway Competence and Projects as a Service›CEMIT is a multi-faceted rail resource that combines the power of software with railway insiders and project managers. Under our Projects as a Service, you will find professional resources that span business development, consulting and project management.

CEMIT is a multi-faceted rail resource that combines the power of software with railway insiders and project managers. Under our Projects as a Service, you will find professional resources that span business development, consulting and project management.

CEMIT AI Data Platform

The Platform represents the foundation of our data analysis software. With the convergence and processing of multiple sensor sources, you get results with meaningful insights, enabling the move towards data-driven decisions and predictive maintenance.

CEMIT AI Data Platform

The CEMIT AI Data Platform is where our AI engine and big data converge. As an agnostic product, it begins with any type of sensor, camera, or data collection tool. Next, it integrates these different siloed information sources into one holistic system. Here, visualization tools do their work, processing and presenting data so employees can make better decisions, on and off the tracks.

A Cloud-Based Data Management Platform

Easy & Universal Installations

Low installation costs, only one platform and elimination of data silos.

Continuous Data Collection

Using in-service trains. “Always on monitoring.”

Reduced Operational Costs

From a limited find-and-fix checklist to a modern predict-and-prevent maintenance solution.

Improved Safety

A safer environment for railway workers keeps boots off ballasts and minimising accidents.

Why Choose the CEMIT AI Data Platform

The CEMIT AI Data Platform gives you the power to make smart, data-driven decisions for your railway operations. No matter your equipment or location details, we can adapt our software to help you solve your particular issue.

The results of single-product versatility are clear: optimal data sharing and streamlined operations. Combined, you have the ideal formula for an economically smart business ready to thrive in a greener world.